Differential pressure table

Model 732.51, chemical industrial, diaphragm metal measuring chamber

Application

Used for measuring corrosive gas and liquid places

Monitoring and control

Filter monitoring

Measurement of material quantity of closed container

Features

Differential pressure measuring range

High work pressure

High overpressure protection

Compatible with electrical contacts and remote transmission

Describion

The special feature of this differential pressure gauge is that it has a high strength corrosion resistant stainless steel structure, a full stainless steel measuring seal, and a long life sealing associated with it

The high strength anti-overload capability is achieved by the way that the entire diaphragm can be attached to the metal bed

High quality stainless steel materials and strong manufacturing structures are suitable for process control with the chemical industry and chemical engineering as well as for liquid and gas media, and are also used in corrosive environments.

Pressure range from 0...

1.6 kpa to zero...

2.5mpa ensures various pressure range requirements

Construction and how it works

The high and low pressure of the measurement chamber are separated by the diaphragm

The bellows isolate the pressure chamber from the atmosphere

Measure the pressure differential between high and low pressure in the dielectric chamber to measure the axial motion of the sensitive element

The measuring bit movement is transferred to the core by connecting rod

The drive core converts the measuring position into pointer drive

The anti-overload performance is achieved through metal bed surface

Technical parameters

Manufacturing structure

Pressure connection radial, bottom, high strength corrosion resistant all-metal structure, measuring chamber safety seal, pressure interface location, can also be determined according to installation requirements

Table circle diameter

Precision grade

Pressure range

The scale length of about 180 can provide other equivalent pressure ranges and vacuum scale

Allowable service temperature

The environment temperature

Medium temperature

Temperature performance

There is a slight error when the temperature of the measurement system is not 20

The maximum display error is for dial calibration

Protection grade

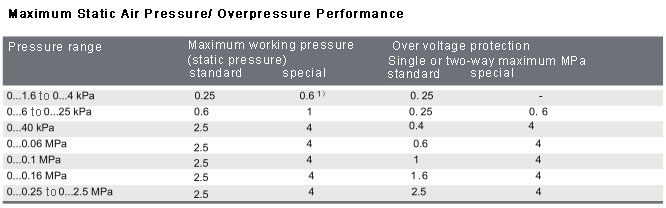

Working pressure and scope of application

Static pressure: full range

Dynamic pressure: 0.9 full range

Standard manufacturing structure

Measuring chamber with pressure interface (contact with measuring medium)

Measuring system sensitive elements

Corrugated pipe

Side face cavity pressure relief

Transmission movement

Stainless steel

The dial

Aluminum, white, black dial letters

Pointer to the

Adjustable pointer, aluminum, black

shell

Stainless steel with pressure relief hole

Table glass

Multilayer safety watch glass

Inlay ring

Bayonet ring, stainless steel

The installation

Press the mark symbol and install

High pressure

The low pressure

Fixed way

Rigid duct type

Measure flange mounting holes

Taking side before

Install on walls or pipes

Optimize for special types

liquid

Strong front manufacturing structure

Higher maximum static pressure and higher overpressure protection

Accuracy above 1.6

When the pressure range is 0.04Mpa, the cavity pressure is measured

Zero setting device

Connect the interface position side

Other pressure connections through internal and external threads

Differential pressure and working pressure are displayed simultaneously

Measuring medium temperature

Install on walls or pipes

Taking side before

Pressure balancing valve

Electric contact switch

transmitter

Ordering Instruction

Model/Table Circle Diameter/Pressure Range/Dial(distribute the pressure or distribute the square/Maximum Air Pressure...Mpa/Pressure Connection Size/Pressure Connection Position/ Optimize For Special Types

|

|